Sandpiper S05 Service & Operating Manual

Non-metallic design level 2

Hide thumbs

Also See for S05:

- Service & operating manual (36 pages) ,

- Service & operating manual (34 pages) ,

- Service & operating manual (25 pages)

Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

Quality System

ISO9001 Certified

Environmental Management System

ISO14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

www.SAndpiperpUMp.cOM

© copyright 2013 warren rupp, inc.

All rights reserved

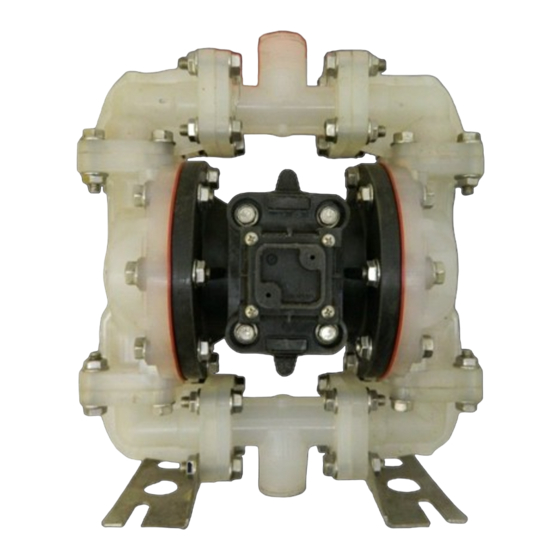

Model S05

Non-Metallic

Design Level 2

d

n

u

o

S

&

h

s

e

M

a l

g r

t e

I n

e r

f l

u f

M

g

n

n i

e

p

m

a

D

.

n

i o

p t

O

w w w

s a n d p i p e r p u m p

n

i o

p t

O

T

R

O

P

E

G

R

T

T

E

L

I N

T

P

N

F

8

3

1

0

d

a r

d

n

a

S t

.

e r

f l

u f

M

c o m

Advertisement

Table of Contents

Summary of Contents for Sandpiper S05

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Model S05 Non-Metallic Design Level 2 Quality System ISO9001 Certified Environmental Management System ISO14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867...

-

Page 2: Safety Information

Refer to nomenclature page for ordering information. WARNING Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers or other miscellaneous equipment must be grounded. Model S05 non-Metallic sandpiperpump s05nmdl2sm-rev0713... - Page 3 • Parts List • Materials Code SECTION 4: aIr ENd ........10 • Air Distribution Valve Assembly • Air Valve with Stroke Indicator Option • Pilot Valve • Intermediate Assembly SECTION 5: wET ENd ........14 • Diaphragm Drawing • Diaphragm Servicing SECTION 6: OPTIONal CONfIGuraTIONS ..16 • Solenoid Shifted Air Valve • Dual Port SECTION 7: warraNTy & CErTIfICaTES ..18 • Warranty • CE Declaration of Conformity - Machinery • ATEX Declaration of Conformity • Explanation of ATEX Certifications Model S05 non-Metallic sandpiperpump s05nmdl2sm-rev0713...

- Page 4 II 2G Ex ia c IIC T5 IEC EEX m T4 II 3/2 G Ex ia c IIC T5 II 2D c iaD 20 IP67 T100˚C II 2D Ex c ia 20 IP67 T100°C note: Pump models equipped with these explosion-proof solenoid note: Pumps ordered with the options listed in (1) are ATEX kit options E1, E3, E5, E7, E8 or E9, are certified and approved by compliant when ordered with kit option P1. the above agencies. They are NOT ATEX compliant. Special condition for safe use: Conductive polypropylene, conductive acetal, or conductive PVDF pumps are not to be installed in applications where the pumps may be subjected to oil, greases and hydraulic liquids. sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713...

- Page 5 Performance S05 NON-mETallIC MODEL S05 Non-Metallic Performance Curve SUcTiOn/diSchArge pOrT Size Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

- Page 6 PART NUMBER MADE FROM UNLESS OTHERWISE SPECIFIED TOLERANCES MATERIAL S05 Non-Metallic Inline Ported Options - THIS IS A PROPRIETARY DOCUMENT. DO NOT REPRODUCE OR DISCLOSE 3.63 92 (Polypropylene Wet End Models Only) .010 GENERAL NOTES WITHOUT THE EXPRESS WRITTEN PERMISSION OF IDEX AODD .XXX...

- Page 7 SUBMERGEd IllUSTRATION primed Fluid MUFFLER 1" DIAMETER AIR LIQUID EXHAUST PIPING LEVEL SUCTION LINE Pump can be submerged if the pump materials of construction are compatible with the liquid being pumped. The air exhaust must be piped above the liquid level. When the pumped product MUFFLER source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills. 1" DIAMETER AIR EXHAUST PIPING LIQUID LEVEL SUCTION LINE sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

-

Page 8: Available Accessories

And Start-Up Locate the pump as close to the product being pumped as possible. Keep the suction line length and number of fittings to a minimum. Do not reduce the suction line diameter. Air Supply Connect the pump air inlet to an air supply with sufficient capacity and pressure to achieve desired performance. A pressure regulating valve should be installed to insure air supply pressure does not exceed recommended limits. Air Valve Lubrication The air distribution system is designed to operate WITHOUT lubrication. This is the standard mode of operation. If lubrication is desired, install an air line lubricator set to deliver one drop of SAE 10 non-detergent oil for every 20 SCFM (9.4 liters/sec.) of air the pump consumes. Consult the Performance Curve to determine air consumption. Air Line Moisture Water in the compressed air supply may cause icing or freezing of the exhaust air, causing the pump to cycle erratically or stop operating. Water in the air supply can be reduced by using a point-of-use air dryer. Air inlet And priming To start the pump, slightly open the air shut-off valve. After the pump primes, the air valve can be opened to increase air flow as desired. If opening the valve increases cycling rate, but does not increase the rate of flow, cavitation has occurred. The valve should be closed slightly to obtain the most efficient air flow to pump flow ratio. sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713... -

Page 9: Troubleshooting Guide

For lifts exceeding 20’ of liquid, filling the chambers with liquid will prime the pump in most cases. Undersized suction line. Meet or exceed pump connections. Pumped fluid in air exhaust muffler. Disassemble pump chambers. Inspect for diaphragm rupture or loose diaphragm plate assembly. Suction side air leakage or air in product. Visually inspect all suction-side gaskets and pipe connections. Check valve obstructed. Disassemble the wet end of the pump and manually dislodge obstruction in the check valve pocket. Check valve and/or seat is worn or needs adjusting. Inspect check valves and seats for wear and proper setting. Replace if necessary. Entrained air or vapor lock in chamber(s). Purge chambers through tapped chamber vent plugs. For additional troubleshooting tips contact After Sales Support at service.warrenrupp@idexcorp.com or 419-524-8388 sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713... - Page 10 WET ENd KIT Seals, O-Ring, Gaskets, Retaining Rings, Air Valve Polyurethane Diaphragms, Nitrile Spacer Gaskets, Assembly Pilot Valve Assembly. Santoprene Check Balls, PTFE Seats and PTFE Seals. 476.202.360 WET ENd KIT 476.202.654 WET ENd KIT Nitrile Diaphragms, Nitrile Check Balls, PTFE Santoprene Diaphragms, PTFE Overlay Seats and PTFE Seals. Diaphragm, PTFE Check Balls, PTFE Seats 476.202.365 WET ENd KIT and PTFE Seals. Neoprene Diaphragms, Neoprene Check Balls, PTFE Seats and PTFE Seals. 476.202.659 WET ENd KIT One-Piece Bonded PTFE/Nitrile Diaphragm, PTFE Balls, PTFE Seats. IMPORTANT NOTE: Polypropylene pumps are shipped with the 1/2" NPT Pipe Plug (item 37) installed in the end ports of both suction and discharge one-piece manifolds. To convert to the Inline porting positions for pump installation and operation, first remove the pipe plugs and re-install in the center ports. Apply PTFE tape or pipe sealant to threads of the plug before installation. sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713...

- Page 11 286.095.360 Diaphragm, Nitrile ............. 2 518.202.552 Inline Discharge Manifold (Polypropylene ONLY) .... 1 286.116.000 Diaphragm, One-Piece, PTFE .......... 2 618.058.552 Plug, 1/2" Pipe (Inline Option Polypropylene ONLY) ..2 720.065.600 Seal, Check Valve Seat (steel seats only) ......8 lEGENd: = Items contained within Air End Kits = Items contianed within Wet End Kits Note: Kits contain components specific to the material codes. ATEX Compliant sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

- Page 12 Many components of SANDPIPER ® 359 Urethane Rubber 661 EPDM/Santoprene ® AODD pumps are made of recyclable 360 Nitrile Rubber Color coded: RED 666 FDA Nitrile Diaphragm, materials. We encourage pump users to 363 FKM (Fluorocarbon) PTFE Overlay, Balls, and Seals recycle worn out parts and pumps whenever Color coded: YELLOW 668 PTFE, FDA Santoprene /PTFE ® possible, after any hazardous pumped fluids are thoroughly flushed. sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713...

- Page 13 For pumps with high Temperature Options: damage the pump, and void factory warranty. 031.194.000 Air Valve Assembly 1-B 031.175.000 Sleeve and Spool Set (Includes all the other items on 031.168.000 above) ATEX Compliant 031.195.000 Air Valve Assembly 031.175.000 Sleeve and Spool Set (Includes on other items on 031.166.000 above) sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

-

Page 14: Parts List

For pumps with Virgin pTFe coated hardware: 031.167.002 Air Valve Assembly Step 8: Reassemble in reverse order. 1-G 675.062.308 End Cap Retainer 1-J 710.011.308 Self Tapping Screw note: Sleeve and spool (1-B) set is match ground to a specified clearance (Includes all other items used on 031.166.000 above) sleeve and spools (1-B) cannot be interchanged. For pumps with alternate Mesh Muffler or piped exhaust: 031.169.000 Air Valve Assembly (Includes all items used on 031.167.000 above minus 1.H, 1.I and 1.J) ATEX Compliant sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713... - Page 15 Reassemble in reverse order. PIlOT VAlVE ASSEMBly PARTS lIST item part number description 095.091.001 Pilot Valve Assembly 3-A 095.087.558 Pilot Valve Body 3-B 755.051.000 Sleeve (With O-Rings) 3-C 560.033.360 O-Ring (Sleeve) 3-D 775.055.000 Spool (With O-Rings) 3-E 560.023.360 O-Ring (Spool) 3-F 675.037.080 Retaining Ring ATEX Compliant sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

- Page 16 (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills. In the event of a diaphragm failure a complete rebuild of the center section is recommended. sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713...

- Page 17 Use With TPE diaphragms Only diaphragm Orientation Install diaphragm and spacer Torque: as shown above. 120 in/lbs diaphragm Service drawing - with Overlay diaphragm Orientation Install diaphragm and spacer Torque: as shown above. 120 in/lbs diaphragm Service drawing - with One-Piece Bonded diaphragm Orientation Install diaphragm as shown above. sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

- Page 18 Most diaphragms are installed with the natural bulge out towards the fluid side. S05, S07, and S10 non–metallic units are installed with the natural bulge in towards the air side.

- Page 19 The rated voltage to the fuse 219.011.004 shall be equal to or greater than the stated rated voltage of the magnet coil. The Solenoid Coil, Single mounting 220/240 VAC, 3.4W / 15mA 1 breakage capacity of the fuse-link shall be as high as or higher than the maximum Note: Item 40 (Conduit Connector) is not required expected short circuit current at the location of the installation (usually 1500 A). A compressed Air Temperature range: Maximum Ambient maximum permissible ripple of 20% is valid for all magnets of direct-current design. Temperature to plus 50°C sandpiperpump Model S05 non-Metallic • s05nmdl2sm-rev0713...

- Page 20 Failure to comply with the 115.144.305 Bracket, Free Standing (replaces 115.140.115) recommendations stated in this manual will damage the pump, and void factory warranty. 115.144.306 Bracket, Free Standing (replaces 115.140.115) 171.068.115 Capscrew, Flanged 5/16-18 X 1.63 171.068.308 Capscrew, Flanged 5/16-18 X 1.63 *Hardware quantities are variable based on porting configurations sandpiperpump • Model S05 non-Metallic s05nmdl2sm-rev0713...

-

Page 21: Declaration Of Conformity

Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include SANDPIPER®, MARATHON®, PortaPump®, SludgeMaster™ and Tranquilizer®. ~ See complete warranty at www. sandpiperpump.com/About/guaranteesandwarranties.html ~ Declaration of Conformity Manufacturer: Warren Rupp, Inc. - Page 22 KEMA 09ATEX0071 X HDF25, HDF2, HDF3M, PB¼, II 1 D c T100 CE 0344 KEMA 09ATEX0071 X S05, S1F, S15, S20, S30, SB1, I M1 c KEMA 09ATEX0071 X SB25, ST1½, ST40, G15, G20, I M2 c KEMA 09ATEX0072 X...