Advertisement

Advertisement

Summary of Contents for Samsung NZ64F3NM1AB

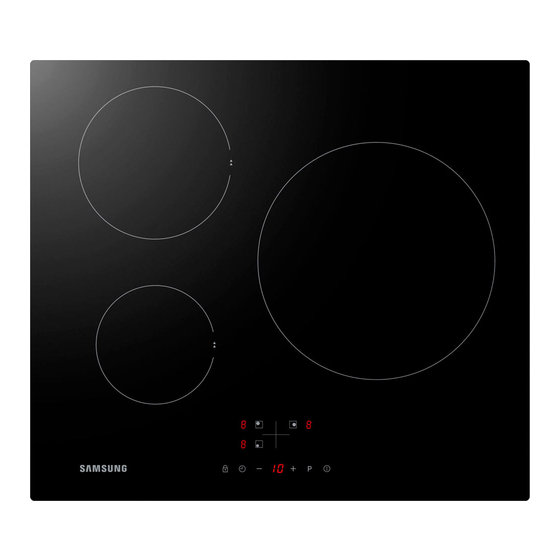

- Page 1 NZ64F3NM1AB NZ63F3NM1AB...

-

Page 2: Table Of Contents

3-1 Replacement of the Ceramic Glass 3-2 Replacement of the Display board 3-3 Replacement of the Coil groupware 3-4 Replacement of the PCB 3-5 Replacement of the Power Cord 5. Wiring Diagrams 5-1 Wiring Diagrams... - Page 3 If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualifed persons in order to avoid a hazard. • 1N ~ • 2N ~ : separate the 2-phase wires (l1 and l2) before connection.

- Page 4 The Principle of Induction Heating: When you place your cookware on a cooking zone and you turn it on, the electronic circuits in your induction hob produce “induced currents” in the bottom of the cookware which instantly raise cookware’s temperature. Induced currents Induction coil Electronic circuits NZ64F3NM1AB NZ63F3NM1AB 1,250W 2,350W 2,350W 1,250W...

- Page 5 NZ64F3NM1AB NZ63F3NM1AB NZ64F3NM1AB NZ63F3NM1AB 10.5 10.6Kg 12.0 12.1...

- Page 6 Induction hob Installation brackets Screws...

- Page 7 before installation. Min. 50 mm Min. 5 mm 560 mm ø 6 90° max. 32 min. 20 Induction Hob min. 5 mm Insulation Panel ventilation gap Oven...

- Page 8 Inatall the two brackets Put into the hole...

-

Page 9: Replacement Of The Ceramic Glass

3 1 Replacement of the Ceramic Glass 1. Disconnect power. 2. Remove 12 screws from 4 edges (3 screws each edge) that are locking the ceramic glass with the radiator board. Ceramic Glass 3.Use the shape "-" group to lift the ceramic glass from the radiator board at the points shown in image 1 (A) with the height shown... - Page 10 140 Coil groupware 220 Coil groupware 220 Coil groupware 140 Coil groupware 1. Remove the 9 screws that securing the base to the screws inside radiator board.And there are 2 more screws inside the power cord case cover. Coil groupware 2.

-

Page 11: Replacement Of The Coil Groupware

3 3 Replacement of the Coil groupware 4. Make the bend part straight. 5. Lift up the coil groupware Coil groupware and through the sensor from the middle of coil groupware. 6. Replace the coil groupware. -

Page 12: Replacement Of The Pcb

3 4 Replacement of the PCB 1. There are 2 Power boards and 1 accessorial power board. Each PCB is securing to the radiator board by 4 screws. Accessorial power 2. Disconnect all wire. board Remove the 4 screws. 3. Replace the accessorial power board. - Page 13 3 4 Replacement of the PCB 2. Disconnect all wire. Remove the 4 screws. 3. Replace the power board. Power board Arrange all wire properly.

-

Page 14: Replacement Of The Power Cord

3 5 Replacement of the Power Cord 1. Remove the base. 2. Remove the 5 screws and take the power cord out. 3. Replace the power cord. 4. After finishing service, Power Cord connect the power cable properly to main power •... - Page 15 IGBT temperature sensor =100K ±5 Ceramic plate =100K ±5 temperature sensor...

- Page 16 Failure Code Problem Solution Unit should operate normally after a few E1/E2 Voltage irregularity minutes and code will disappear from display. Wait for temperature to return to normal. E3/E4 High temperature of ceramic plate Push “ON/OFF” button to restart unit. Wait for temperature to return to normal. Push “ON/OFF” button to restart unit. E5/E6 High temperature of hob Check if the fan runs smoothly. Fan should be replaced by a new one if not work anymore. Ceramic plate temperature sensor ...

- Page 17 Ceramic plate temperature sensor Short Error (F3/F6) Yes Remove any foreign substance Is the sensor terminal part : check if the sensor and related from the shorted part. of the PCB shorted? parts such as the connector or soldering parts are slightly shorted. No No Push “ON/OFF” button No Is the sensor’s real resistance to restart unit, does the is shorted circuit? symptom continue? Yes Yes The sensor has defected. Replace the sensor.

- Page 18 Ceramic plate temperature sensor Open Error (F4/F7) No Connect the sensor. : check if the sensor wire is damaged. Is the sensor connected? Replace the sensor. Yes Is the sensor wire No connected properly Connect the wire properly. by burner position? Yes Push “ON/OFF” button No No Is the sensor’s real resistance to restart unit, does the is opened circuit? symptom continue? Yes ...

- Page 19 Ceramic plate temperature sensor Failure Error (F5/F8) No Adjust sensor to the Is the sensor in the right position? properly position. Yes The sensor has defected. Replace the sensor. Perform the operation again and check if it is working properly. - 17 -...

- Page 20 IGBT temperature sensor Short Error (F9/FC) Yes Remove any foreign substance Is the sensor terminal part : check if the sensor and related from the shorted part. of the PCB shorted? parts such as the connector or soldering parts are slightly shorted. No No Push “ON/OFF” button No Is the sensor’s real resistance to restart unit, does the is shorted circuit? symptom continue? Yes Yes The sensor has defected. Replace the Power board.

- Page 21 IGBT temperature sensor Open Error (FA/FD) No Connect the sensor. Is the sensor connected? : check if the sensor wire is damaged. Replace the Power board. Yes No Push “ON/OFF” button No Is the sensor’s real resistance to restart unit, does the is opened circuit? symptom continue? Yes Yes The sensor has defected. Replace the Power board. Replace the display board. Perform the operation again and check if it is working properly. - 19 -...

- Page 22 4-3 Electrical Malfunction Failure Problem Solution The LED does not come NO power supplied or display is on when unit is plugged 21 Page damaged. in. Some buttons can’t work, or the LED display The display board is damaged. 22 Page is not normal. The Cooking Mode There is something wrong of the indicator comes on, but 23 Page fan or the power board is damaged. heating does not start. Heating stops suddenly Cooker has overheated or the pan during operation and 24 Page type is wrong. display “U” Heating zones of the same side (Such as the Communication failure 25 Page first and the second zone) would display “U”. Fan motor sounds The fan motor is damaged or Replace the fan. abnormal. foreign body inside. ...

- Page 23 4-3 Electrical Malfunction The LED does not come on when unit is plugged in No Connect the display board to the : Check to see if plug is secured tightly in Check the connection. accessorial power board properly. outlet and that outlet is working. Check if the accessorial power board and the display board are connected properly? Yes ...

- Page 24 4-3 Electrical Malfunction Some buttons can’t work Yes Is the button not recognized at all? No Yes Is the button recognized intermittently? No Is the button not Yes recognized after cleaning the control panel? No The display board is defective. No Push “ON/OFF” button to restart unit, does the symptom continue? Replace ...

- Page 25 4-3 Electrical Malfunction The Cooking Mode indicator comes on, but heating does not start Yes Ensure that the airflow Check if the Air Intake or is smooth. Air Vent is blocked. No No Check if the fan runs Replace the fan. smoothly. Yes No Push “ON/OFF” button to restart unit, does the symptom continue? Yes The power board is damaged Replace the Power board.

- Page 26 4-3 Electrical Malfunction Heating stops suddenly during operation and display “U” Yes Use the proper pot (refer to Check if the pot type is the instruction manual). wrong. No Yes Use the proper pot (refer to Check if the pot diameter is the instruction manual). too small. No No Push “ON/OFF” button to restart : Unit is overheated. Wait for unit, does the symptom continue? temperature to return to normal. Yes The pot detection circuit is damaged, ...

- Page 27 4-3 Electrical Malfunction Heating zones of the same side would display “U” No Connect the display board to the : Check if the Power board and the Check the connection. Power board properly. display board are connected properly? Yes Connect the display board Yes Connect a test display board to Yes to a test Power board. : Test board, means a normal the Power board. Restart the unit, ...